Lean Six Sigma Training Singapore

Why train your employees?

In today’s fast-changing business environment, organizations are constantly pushed to innovate and improve. To do that, the ability and competency of the employees are key. Therefore, it is paramount that organizations constantly equip employees with the knowledge and skills to “Learn, Unlearn and Relearn”

CFO: What happens if we train them and they leave?

CEO: What happens if we don’t and they stay?

“Learning is an experience. Everything else is just information”

At Lean Institute Asia, we don’t train, we engage and encourage participants to learn. We believe learning should be enjoyable and fun, as such we design all our courses to facilitate different adult learning styles. This is to ensure effective transfer of knowledge and skills to the learner.

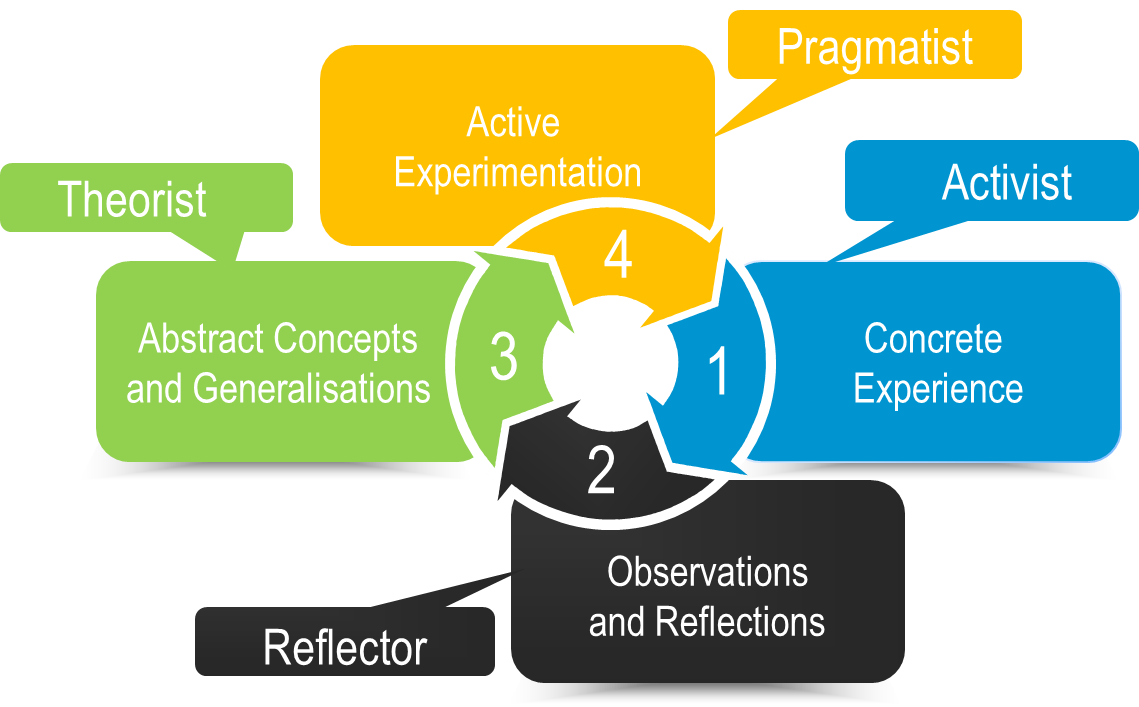

According to acclaimed American educational theorist David Kolb’s paper published in 1984, effective learning happens when a person goes through four stages in the experiential learning cycle, refer to diagram on the right, (1) going through a concrete experience followed by (2) observations and reflections on the concrete experience which results in (3) the development of abstract concepts (analysis) and generalisations (conclusions) which lead to (4) active experimentation of the conclusions (hypothesis) in future situations, results in new learning experiences.

Kolb’s Experiential Learning Style

Why attend Lean Six Sigma training?

Lean and Six Sigma are two fundamental methods in the continuous improvement to drive efficiency and effectiveness in organizations. The trainings are designed to impart the participant’s time-tested problem-solving framework and tools to tackle the different type of challenges at work. Lean training focuses on eliminating different types of process wastes to deliver maximum customer value. On the other hand, Six Sigma training focuses on identifying the key factors in the process that caused the product or service not meeting customer specifications. By eliminating process wastes and defects, it will result in significant improvement in customer satisfaction and business profitability.

Our In-House Learning Modules

We provide a suite of standard continuous improvement training that can also be customized according to your needs. Our training courses are designed and delivered by consultants who have deep expertise in Lean Six Sigma and experience in conducting trainings in Asia and the Middle East. The following are the list of corporate in-house training courses and workshops that we provide. More course outline and details are available upon request.

Lean Management

Lean Leadership

Lean 5S

Hoshin Kanri (Policy Deployment)

Value Stream Mapping

Visual Management

Standardized Work

Basic Structured Problem Solving

Lean Six Sigma Yellow Belt Certification

This course will equip participants with foundational Lean Six Sigma tools and techniques to enable them to lead and solve yellow belt level business opportunities or process improvement issues. Yellow belters typically spend around 10% to 20% of their time on Lean Six Sigma projects. This training course will lead to yellow belt certification.

Lean Six Sigma Green Belt Certification

This course will equip participants with intermediate Lean Six Sigma tools and techniques to enable them to lead and solve green belt level business opportunities or process improvement issues. Green belters typically spend around 20% to 40% of their time on Lean Six Sigma projects. This training course will lead to green belt certification.

Lean Six Sigma Black Belt Certification

This course will equip participants with advanced Lean Six Sigma tools and techniques to enable them to lead and solve black belt level business opportunities or process improvement issues. Black belters typically spend around 80% to 100% of their time on Lean Six Sigma projects. This training course will lead to black belt certification.

Lean Six Sigma Train the Trainer Certification

In any lean six sigma deployment, there is a need to create internal capabilities to impart lean and six sigma knowledge, tools and techniques to other parts of the organization. Our highly effective train the trainer course is designed to develop the training knowledge and skills of your lean six sigma practitioners. This training course will lead to lean six sigma trainer certification.

Testimonials

Fantastic! Very personal delivery and interactive lean six sigma training course! I rate it 5 out of 5

Ms TamayoThe lean six sigma trainer was very facilitative and was able to capture the attention of the particpants at all times!

Mr BusafiThe lean six sigma workshop is Fun, Interactive and creative that i ever attended

Mr AgungTraining Feedback from Participants

%

Rated a training Excellent

%

Strongly Agree it achieve the training objectives

%

Strongly Agree it meets their personal goals

%

Strongly Agree trainer has successful engaged them

Want more information?

Drop us a line anytime, and one of our customer service reps will respond to you as soon as possible